No one will ever mistake mining for an easy job.

It’s demanding work that requires durable tools, which is where RAD Torque Systems comes in.

RAD tools are used in a number of critical industries, including wind energy, oil and gas, aerospace and, for the purposes of this article, mining. Read on to learn why these are the ideal torque wrenches for quarry and mining operations.

RAD torque wrenches for mining

RAD torque wrenches for mining

The mining industry relies on heavy duty trucks to transport extracted materials off-site safely and expediently. When one of those trucks needs repair or maintenance, getting it in motion again is vital for your business.

That’s what RAD – and Maxpro – have learned from years of working with some of the biggest mining companies on the planet. We know the pressures mining crews face, which is why RAD has designed tools that minimize downtime and maximize torque. RAD tools are designed with mining in mind.

Quick changes

The giant haul trucks going in and out of mining operations regularly need maintenance and new tires. With RAD’s lightweight torque wrenches for mining, workers can have those tires changed in no time.

Safer workers

Safer workers

Working in a mine is a physically taxing job, which is why RAD has designed torque tools that are ergonomically friendly.

Instead of working with hefty impact wrenches – which have a heavy impact on workers’ bodies – you get a tool with no impact. Just set the wrench to a specific torque and trust that it will be accurate to plus or minus five percent.

Faster hauling

Haul trucks are a specialty for RAD. Their wrenches are used not only for replacing tires, they also supply strut kits for the Caterpillar 797 and the Komatsu 980, as well as tools for engine barring, cutting blades, final drive segments, wheel nuts, mill liners and tie rod bolts.

Some of RAD’s more popular torque wrenches for mining include:

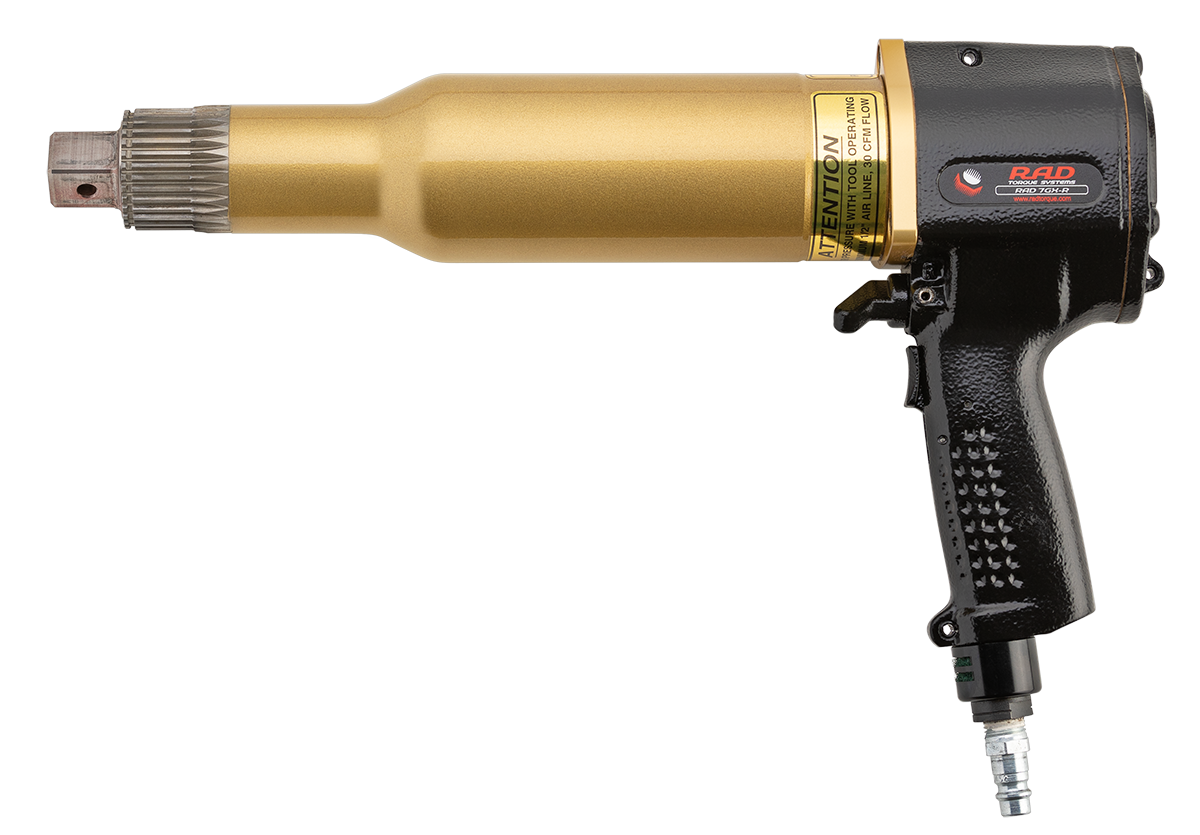

The RAD Single Speed

The RAD Single Speed

These are extreme torque wrenches designed for heavy duty

applications and features:

- The best power-to-weight ratio

- Wide torque range for multiple applications

- Unmatched reliability from one of the most advanced engineered gear boxes available

The RAD Transducer Verification

These torque wrenches with built-in transducers for verification and traceability include:

- Easy data collection

- Pass/fail indicator light

- Bluetooth connectivity to your tablet or phone

- Controlled torque accuracy of plus or minus one percent on the

transducer

RAD Wheel Nut and OTR mining

The RAD wheel nut tool has one job – to provide wheel nut bolting where torque control is critical. This mining tool features:

- Removable custom reaction arms designed for almost any wheel configuration

- Extended reaction point for quick, safe operation

- Accuracy to ensure wheels are properly tightened

Maxpro is proud to be the eastern seaboard’s leading supplier of RAD torque wrenches for quarry operations and mining companies.

And we not only sell, rent and repair RAD tools, we can make sure they’re properly calibrated at our A2LA-accredited lab.

Contact us today to learn more about RAD torque wrenches for mining and how Maxpro can help make your operation a safer, more efficient space.