In our last blog post we discussed some common indirect bolted joint tensioning methods, including torque control, torque and turn control, and stretch control.

Some of these methods offer more precision than others, although none offer direct control over the tension created in the fastener the way the following methods

can.

Washer Control

Washer Control

Simple, inexpensive tension control systems use DTI washers (for “direct tension indicating”). These are washer load cells made with raised dimples that indicate when the correct tension level is reached.

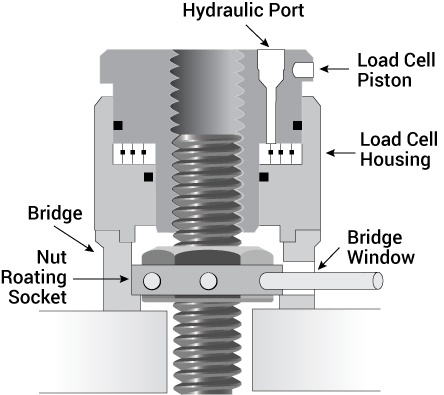

Hydraulic Tensioners

These are tools used to tighten large diameter bolts. It involves an upper collar that’s threaded over the exposed thread above the nut. Hydraulic pressure pulls up on the bolt. From there, the nut is run down against the upper part of the joint. When the pressure eases, the nut still holds most of the tension that has been created.

These are tools used to tighten large diameter bolts. It involves an upper collar that’s threaded over the exposed thread above the nut. Hydraulic pressure pulls up on the bolt. From there, the nut is run down against the upper part of the joint. When the pressure eases, the nut still holds most of the tension that has been created.

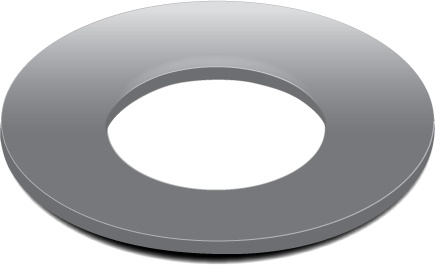

Disc Spring Washers

Like their name suggests, these washers use a spring-like action. Placed under the head or nut, these washers begin to deform as the fastener is tightened, allowing them to push upward.

Like their name suggests, these washers use a spring-like action. Placed under the head or nut, these washers begin to deform as the fastener is tightened, allowing them to push upward.

The washers can be used one at a time, or in stacks to alter the level of deflection. When stacked in the same direction, they create a stiffer joint. When stacked in an alternating direction, the washers create greater deflection.

Ultrasonic Instruments

These tools emit a short burst of ultrasound into the bolt, calculating the time it takes for the sound to echo off the end and come back to the transducer.

As a bolt stretches, the time it takes for that signal to return will increase. This is a costly method that requires several different components, and as such is used rarely.

As a bolt stretches, the time it takes for that signal to return will increase. This is a costly method that requires several different components, and as such is used rarely.

Do you need to ensure your fasteners have reached the proper torque or tension? Contact Maxpro. In addition to selling top quality torque and tension tools, we offer the services of our A2LA-accredited calibration lab, where we can make sure the tools you use give you the accurate readings you need.