There’s been a lot of advances in battery technology over the last five years, and this has led to changes in many industries, including the torque tool and bolting field.

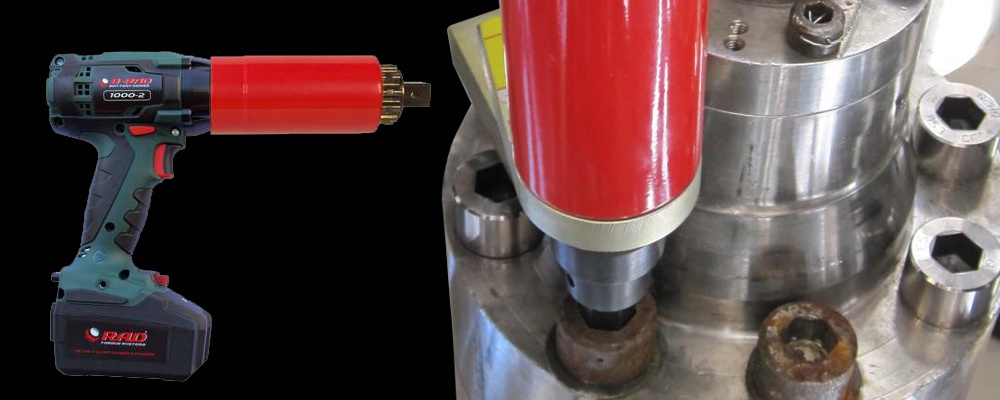

The first high capacity battery torque wrenches were introduced about 10 years ago when New World Technologies launched their B-RAD series tools.

These tools had a maximum capacity – at that time – of 1300 foot pounds and worked on voltage controlling a clutch to give a reasonably accurate torque output tool.

Today most battery torque wrenches are electronically and digitally controlled, much more accurate, and feature a wider and higher torque range capacity, along with a longer battery life.

Today most battery torque wrenches are electronically and digitally controlled, much more accurate, and feature a wider and higher torque range capacity, along with a longer battery life.

With these advances, many industrial customers have begun considering trading their pneumatic or electric torque wrenches to new battery torque wrenches.

Here are a few pros and cons of making that change.

Positives:

- No power cord or airline required.

- Have electronic features that pneumatic tools can’t offer.

Negatives:

- Battery has a cycle life and may need to be changed out/recharged often

- Simply not as durable as a pneumatic or electric torque wrench

- Accuracy and torque repeatability tend to be less with battery tools

- The motors in battery torque wrenches are not as robust as pneumatic or electric tool motors, which means the tools have an overall lower life span.

Battery torque wrenches have their place in heavy industry, but customers should be aware of being oversold by the pure fact they do not have a cord or airline attached. You must consider all your options before making this capital tool purchase or change over to battery torque tools.

No matter what torque tool you decide to use, count on Maxpro to help. We are a leading solution provider of all style torque tools: battery, pneumatic, electric, hydraulic and manual.

We can work with the customer to provide what the best answer is for the customer’s needs and application. Contact us today to find out how we can help you finish your next project.